Christmas Pudding Coins in Silver

A set of 6 deluxe solid silver Christmas pudding coins, charms or tokens, each with a different vintage illustration. A perfect family heirloom: exchange for real money on Christmas Day and use them for many years to come.

Orders ship from Australia

-

I gave my mum a set of your pudding coins for Christmas - she cried and said she had never been given such a beautiful gift.

You'll love making precious new memories every Christmas with these high quality solid sterling silver Christmas pudding coins: we do just that in our own family.

Mixing silver Christmas pudding coins, tokens or charms into plum pudding for luck is a very old, quirky and fun Christmas tradition. If you find one or more silver coins in your slice of plum pudding it's said to bring you good luck and wealth in the new year. Learn about the history and traditions of Christmas puddings and coins.

You can press the coins into any Christmas pudding prior to serving (which we recommend), but you can also bake them in. The Christmas coins can be exchanged for real money to ensure you get them back again, making them a perfect family heirloom you'll use for many years to come.

Our Christmas pudding coin sets have been produced by us for over 15 years: in that time hundreds of sets have been delivered to families around Australia and the world and they've been featured in numerous magazines and blogs.

Note: You may receive a larger sized gift box than the one photographed.

About the coins:

The solid silver coins come in sets of 6. They are larger and thicker than traditional threepences and sixpences, making them more valuable and much easier to find in your pudding. Each Christmas coin is etched with a different vintage Christmas illustration: much more unique than all identical coins and you can attach your own meanings to each coin, adding to the fun.

The pudding coins are made from solid sterling silver. The illustrations have been darkened and the coins have been given a bright and shiny polished finish.

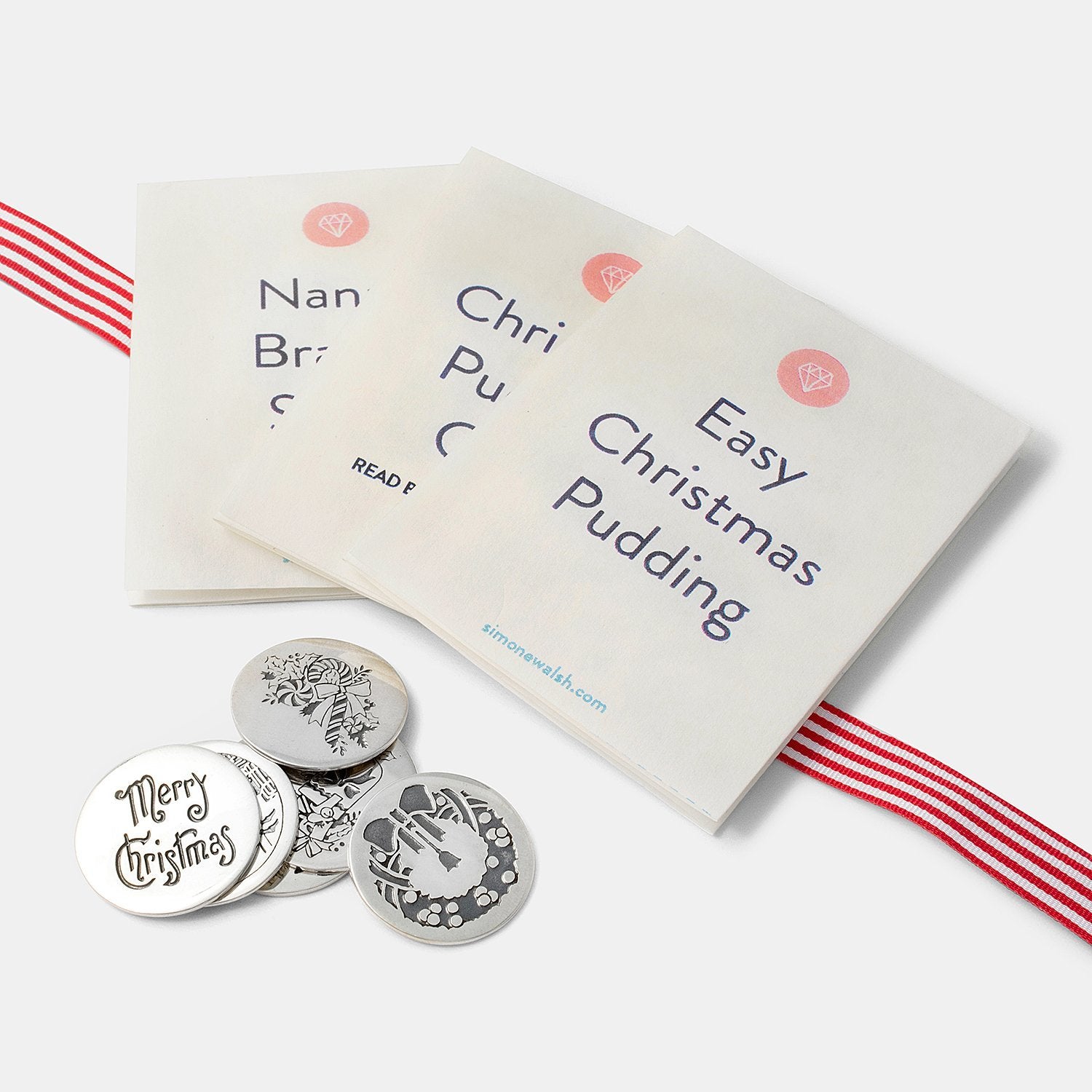

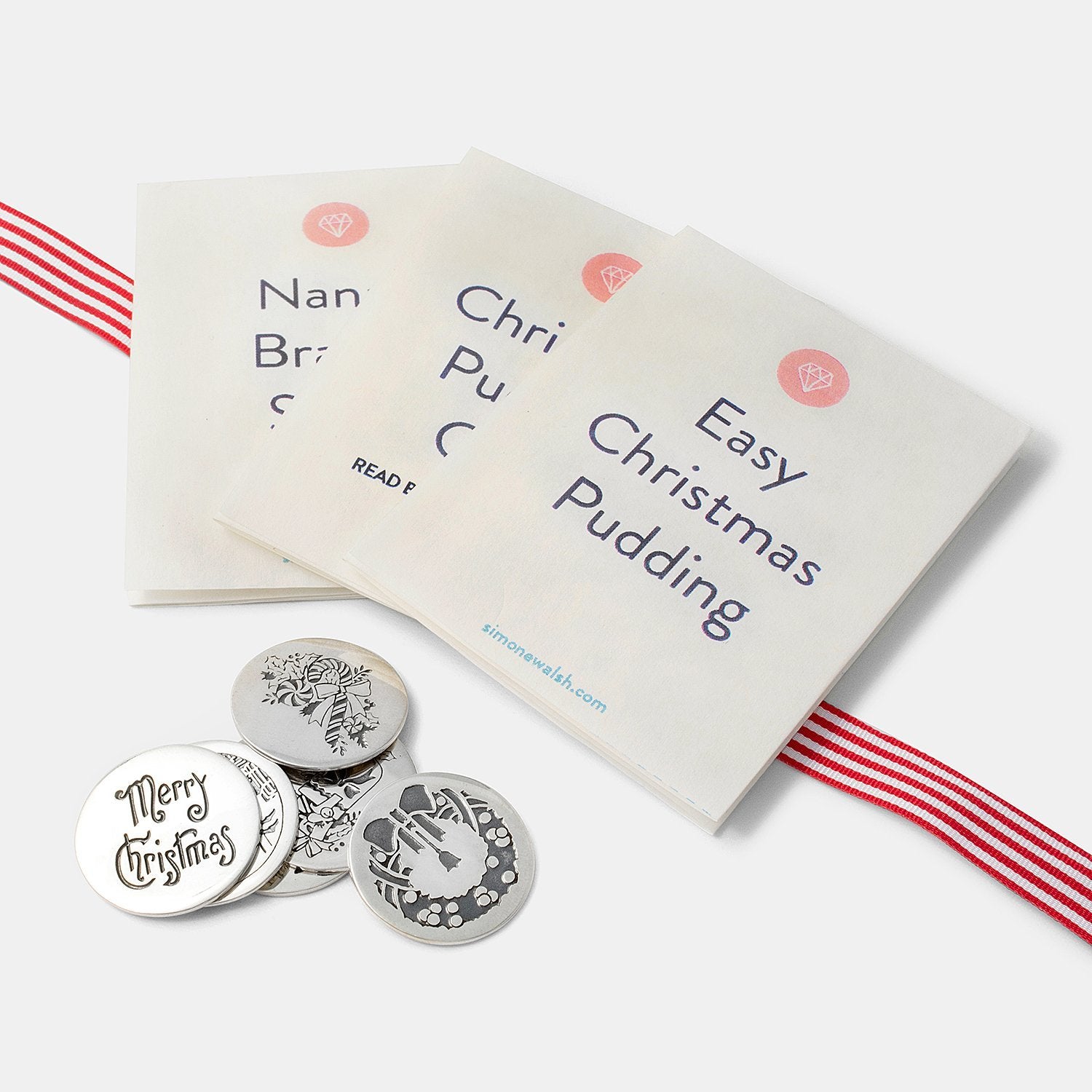

The coins are accompanied by free recipes and care instructions.

What you'll get with your coins:

Your Christmas pudding coins come in a sturdy white cotton-filled box so you can keep them safely packed away during the year. The box is tied with a festive red and white striped ribbon.

Your Christmas coins set will include:

- 6 large solid sterling silver Christmas pudding coins

- A very quick and easy Christmas pudding recipe to make on the day

- Delicious and indulgent brandy sauce recipe

- Use and care instructions

- A sturdy cotton filled box for storing your Christmas coins

Learn about the history and traditions of Christmas puddings.

As seen in:

- Australian House & Garden magazine

- Country Style magazine

- Not Quite Nigella blog

- ... And many more

PS. If you're shopping for Christmas gifts, you should check out our Christmas Shopping Guide. Also take a look at our Australian jewellery, including our gold jewellery, silver jewellery and gemstone jewellery.

Just the facts:

- Quantity: six large solid silver Christmas pudding coins, each with a different vintage Christmas illustration.

- Materials: Food grade sterling silver. The Christmas coins come in a small cotton-filled box with a candy cane striped ribbon, free recipes and instructions - with extra good luck included.

- Size: Each coin is approximately 2cm (0.8") in diameter.

- Thickness: Each coin is 0.8mm (0.3") thick.

- Note: Use of these coins is at your own risk. You must advise guests that coins are in the pudding. Never serve food containing coins to young children.

- FREE shipping Australia-wide on orders over $100. Learn more.

- Shop with confidence! Our happiness guarantee* ensures you'll love your jewellery — or your money back.

- Each piece arrives beautifully packaged in an eco-friendly gift box, complete with care instructions.

- Sending a gift? Ship directly to your recipient with a personal note. You can also add a greeting card or gift wrapping at checkout. Invoices are never included.

- Secure checkout with multiple payment options: credit card, PayPal, Shop Pay, Afterpay (Australia), Google Pay, and Apple Pay.

* Terms and exclusions apply (especially for rings). See full details.

Choose options