Shop Earrings Australia Online

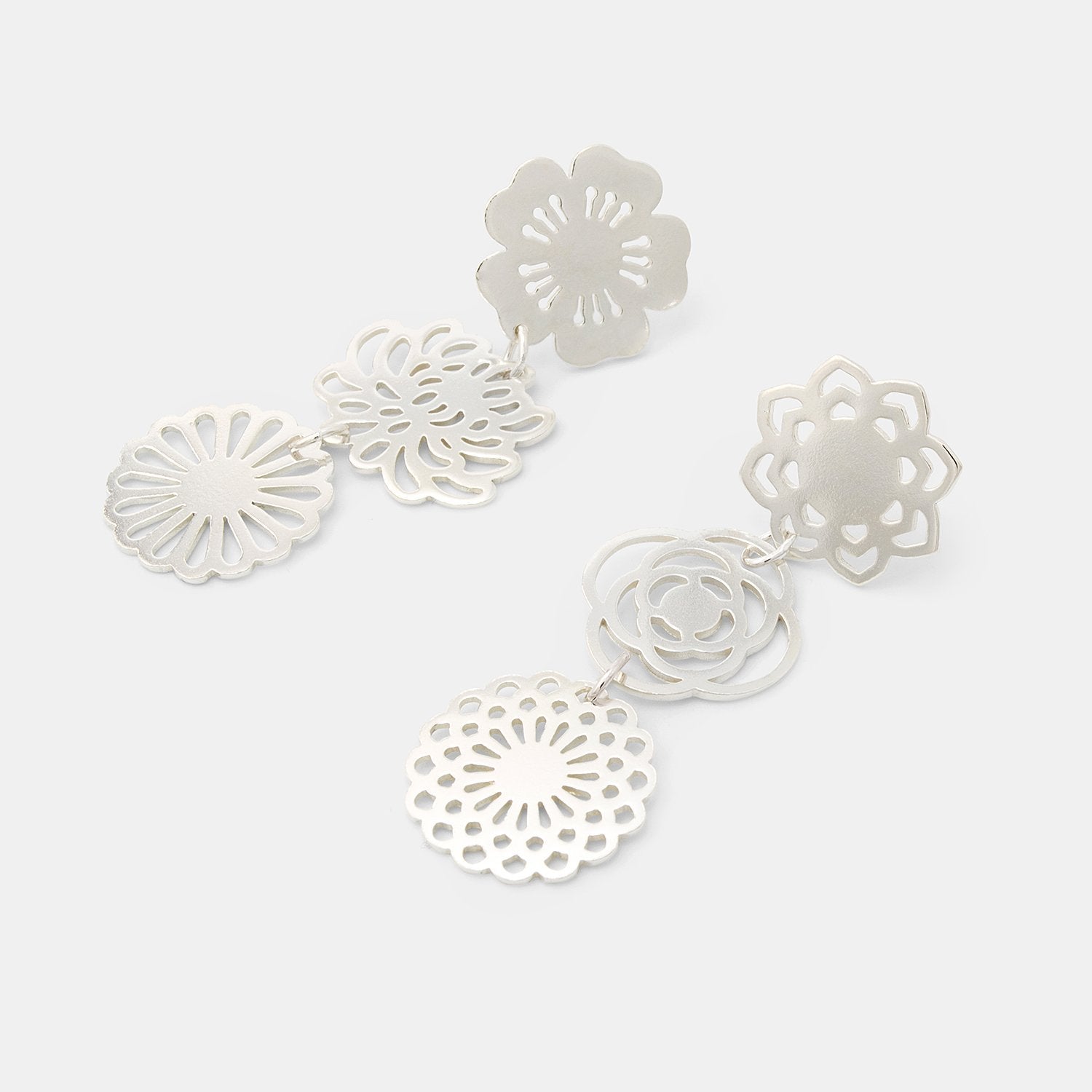

Discover our thoughtfully designed collection of Australian earrings, crafted in sterling silver and gold. From subtle everyday styles to bold designs that turn heads, you're sure to find unique earrings that suit your personal style.

Looking for something specific? Explore these curated collections:

Not sure what to choose? Check out our guide to Different Types of Earrings.

All of our handmade earrings are created by Australian jewellery designer Simone Walsh and made to be worn and loved every day. We offer fast and free shipping Australia-wide and your order will arrive in beautiful, eco-conscious packaging.

Whether you're shopping for yourself or looking for a special gift, we make it easy to find meaningful, wearable designs. Explore our full Australian jewellery range, including ethical and sustainable jewellery created with care.

Want to complete the look?

Browse our matching collections: Necklaces Australia | Bracelets Australia | Rings Australia