Recently a loyal customer asked if we would make a pair of earrings and matching pendant in an older design which is no longer in production in the online jewellery shop.

This is a very old blog post. Visit the Jewellery Blog for the latest.

Also explore our Australian Jewellery Range.

The pieces were to be given as a gift to a relative of the customer who had wanted these particular designs for some time.

Now the gift giving is done, I thought I'd share a bit of an insight into the making process and show the finished pieces.

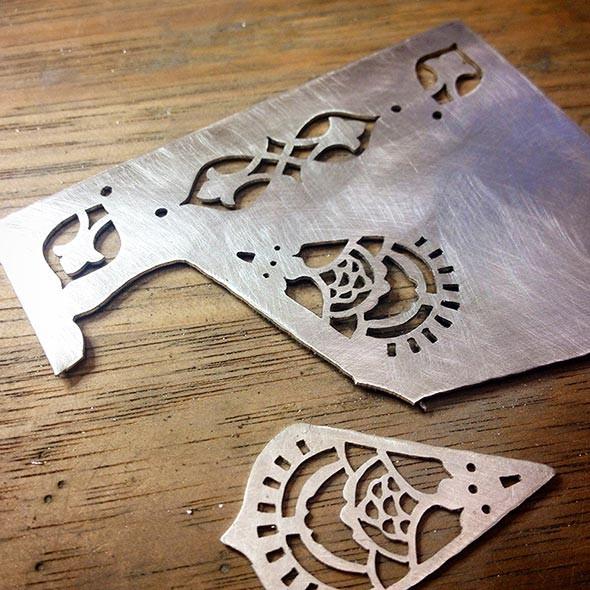

The pieces were all sawn out by hand in flat sheets of sterling silver. In the top right image you can see that the internal fretwork for the pendant has been saw-pierced out and underneath are the drilled holes so I could start sawing the matching pair of earrings.

Once the fretwork saw-piercing was completed I sawed out the outlines to give me the three separate pieces.

The individual pieces were then filed and sanded to clean them up. They were then heated and given a domed shape and finally the pendant bail was soldered closed.

The bottom right image shows the pieces after being completed to this point. They were then tumbled with stainless steel shot overnight to make them bright and shiny, so the pieces could be assembled as a finished pendant and earrings, as seen to the left.

The design for these pieces is based on a Victorian-era absinthe spoon.

Read other top jewellery making articles:

- Watch our sterling silver chain being handmade

- Making sterling silver earrings

- Very intricate saw piercing for jewellery

- What it means to truly support local designers and artisans

Simone Walsh is a

Simone Walsh is a